bespoke bicycle co.

bespoke is an independent research project aimed at cnc-machining a wooden bicycle frame.

our mission is to create a bike with the smoothest ride, best pricepoint, & freshest look.

wooden bikes existed for decades before the steel frame became the norm.

with modern manufacturing techniques, wood has the potential to perform better than steel, aluminum, and carbon.

benchmarking

renovo bikes

industry leader in wooden bikes

drawbacks: $5-6000 frame, 6 week manufacturing time

bsg bikes

plywood frame, urban style

drawbacks: $3300 price, heavy construction, steel rear triangle

sandwich bikes

flat-pack DIY wooden bike

drawbacks: ugly as sin, comes unassembled

bespoke’s design objectives

lightweight frame – < 20 pounds to compete with modern fixie road bikes

smooth ride quality – harness wood’s flexibility to dampen road vibrations

low cost of manufacturing – beat the competition with a < $1k price point

initial prototype

objective: prove a wooden bike frame can be CNC-machined in two halves.

2nd generation

form exploration through sketches

3d modeling

objective: model a custom frame around standard bike parts in SolidWorks

a steel 1980’s Schwinn single-speed is scrapped for the prototype.

62 parts were salvaged.

a total of 87 parts were modeled in SolidWorks to the micrometer.

every nut, bolt, thread pitch & revolution. every chain link.

exploded view – 87 parts

every part & assembly file for this render is available for personal use.

[ solidworks 2015 ]

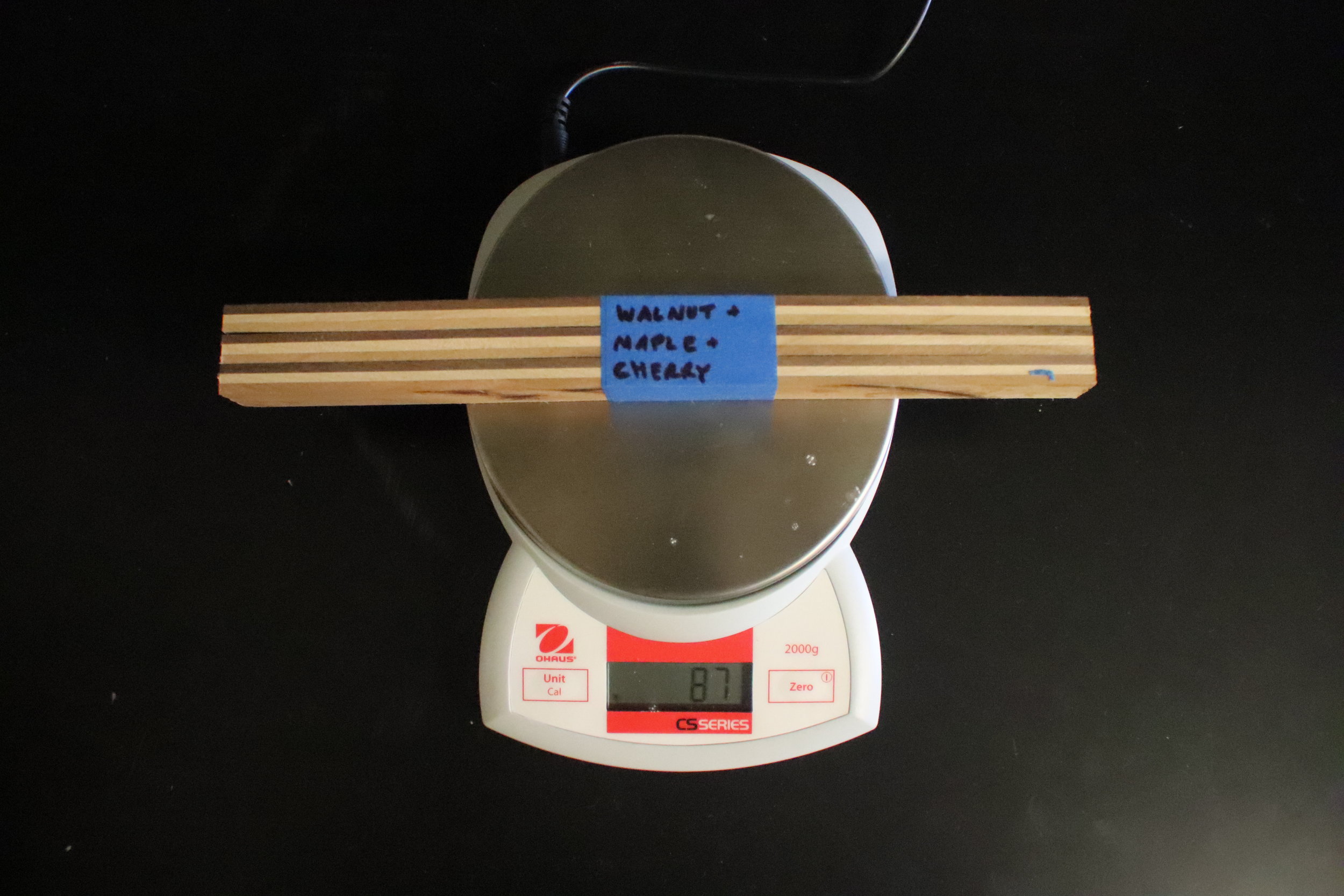

material testing

various wood species were laminated into strips to test strength-to-weight ratio and flexibility.

the strips were then placed on a breaking jig and weight applied until catastrophic failure.

material considerations

flexibility

it must flex slightly to dampen road vibrations.

cherry and maple are the most flexible options.

weight

it must be light.

maple and poplar are the lightest options.

strength

it must stand up to daily abuse.

maple achieved a load of 34 kg before failure.